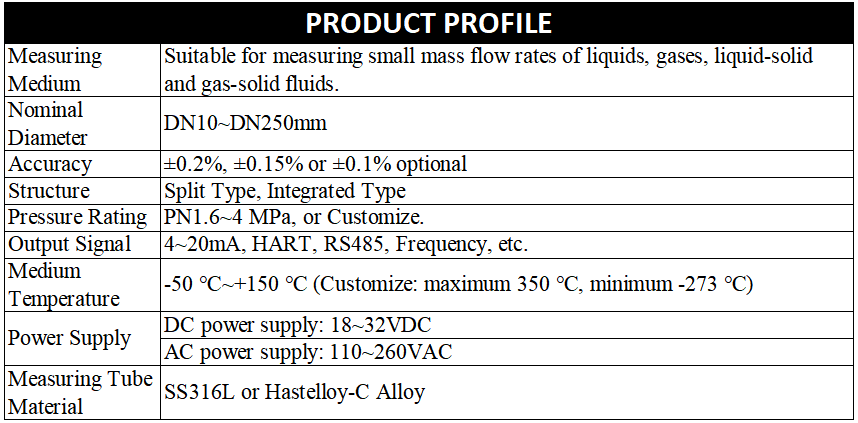

Coriolis Mass Flow Meter

The mass flow meter is based on the Coriolis principle and uses a magnet and coil assembly installed on the measuring tube to cause the measuring tube to vibrate in a reciprocating cycle at a fixed frequency under the action of alternating current. When the industrial process fluid medium flows through the measuring tube, the Coriolis force effect will occur, and the two measuring tubes will undergo torsional vibration. At this time, the detection coils installed at both ends of the measuring tube will generate two signals with different phases. The phase difference is proportional to the fluid mass flowing through the sensor measuring tube. Therefore, the fluid mass value can be obtained by measuring the phase difference.

Features:

Being able to directly measure the mass flow rate of fluids (which is of great significance for energy metering andchemical reaction detection and control in production processes).

High measurement accuracy (can be guaranteed to be between 0.1% and 0.5%).

Wide application range. in addition to normal fluid measurement, it can also measure industrial medium that aredifficult to measure with general fluid measurement instruments, such as non Newtonian fluids, various slurries, suspensions, etc.

The installation requirements are not high, There is little requirement for the upstream or downstream straightpipe section.

Reliable operation, low maintenance rate.

INQUIRY

Categories

Latest News

Contact Us

Contact: Jasmine

Phone: +86-13764578878

E-mail: info@meterins.com

Whatsapp:8613764578878

Add: No. 23, Lane 328, Minle Road, Haiwan Town, Fengxian District, Shanghai, China 201419